In the world of warehouse automation, roller conveyors have become essential. Industry expert John Smith once said, "A well-designed roller conveyor system streamlines operations." This highlights the importance of understanding these systems.

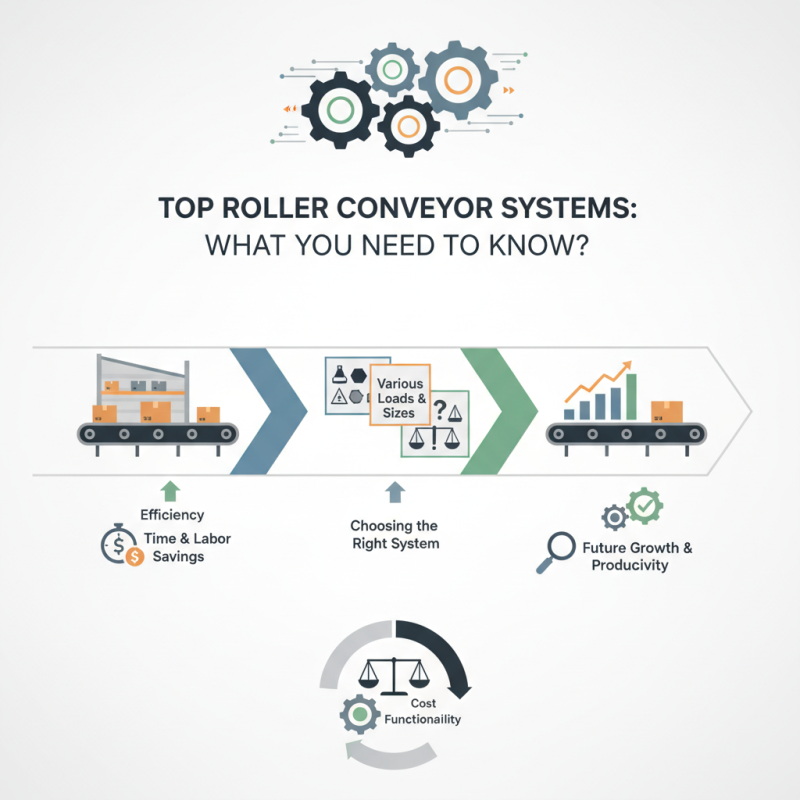

Roller conveyors help move products efficiently, saving time and labor. They can handle various loads and sizes. However, choosing the right system can be tricky. Not all roller conveyors are created equal. Factors like weight capacity and surface type must be considered.

Some companies overlook these details, leading to inefficiencies. The right roller conveyor system should not only meet current needs but anticipate future growth. Finding balance in cost and functionality requires careful thought. Understanding these factors can lead to improved productivity and reduce operational hiccups.

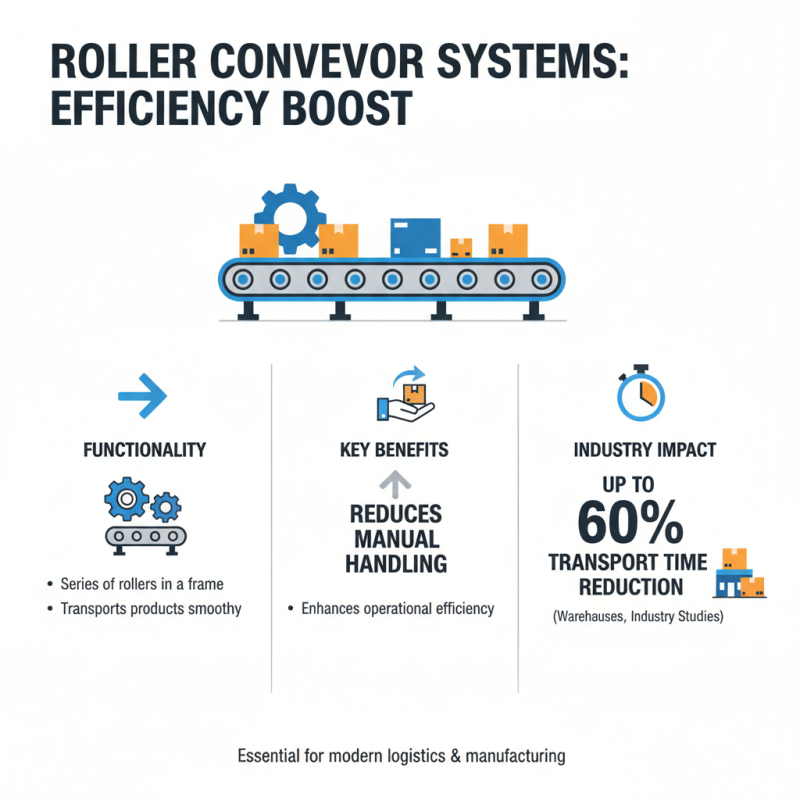

Roller conveyor systems are essential for moving goods in various industries. These systems utilize a series of rollers arranged in a frame to transport products smoothly. They reduce manual handling and enhance efficiency. In warehouses, for instance, up to 60% of transportation time can be cut down with these systems, as reported by industry studies.

Understanding how roller conveyors work is crucial for effective implementation. They rely on gravity or motors to facilitate movement. Roller surfaces support items as they move, allowing for a safer transfer. However, improper alignment can lead to product jams and delays. This is a concern that must be addressed.

Tips: Ensure regular maintenance checks on your roller conveyor. Misalignment can lead to costly downtime. Proper documentation helps track equipment performance and maintenance schedules. Additionally, consider the weight and size of items before installation. Overloading can cause mechanical failures and hinder productivity. Always assess your needs carefully.

Roller conveyor systems are essential in many industries. They facilitate the transport of materials and products efficiently. Understanding the different types is crucial for optimizing operations.

There are several types of roller conveyor systems. The most common are gravity rollers, powered rollers, and accumulation rollers. Gravity rollers rely on slopes for movement. They are ideal for lightweight materials. Powered rollers use motors to control speed and direction. These systems are perfect for heavy, bulky items. Accumulation rollers allow products to stop without blocking the system.

Tips: When selecting a roller conveyor, consider the product size and weight. Test the system with mock loads. This ensures optimal performance. Speak to experts about potential layout changes, as poor layouts can hinder efficiency. Don't overlook the importance of regular maintenance. Neglecting this can lead to system failures. Your operations should be both effective and adaptable.

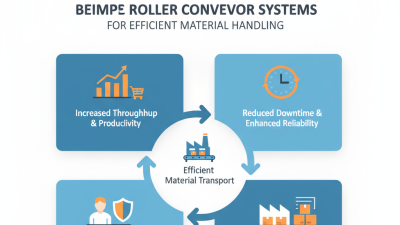

Roller conveyor systems are essential in modern material handling. They help streamline the movement of products throughout warehouses and factories. Understanding the key components of these systems is vital for effective operation and maintenance.

One major component is the rollers themselves. They support the weight of goods and allow them to move smoothly. Rollers come in various sizes and materials. Choosing the right type is crucial. Poor selection can lead to system failures.

Another key element is the frame. It provides stability and support to the entire system. A sturdy frame can prevent misalignment and accidents. Additionally, supports and end stops are necessary for safety. Without them, heavy loads can cause injuries or damage. Regular inspection of these components is important. Ignoring wear and tear can result in costly downtime.

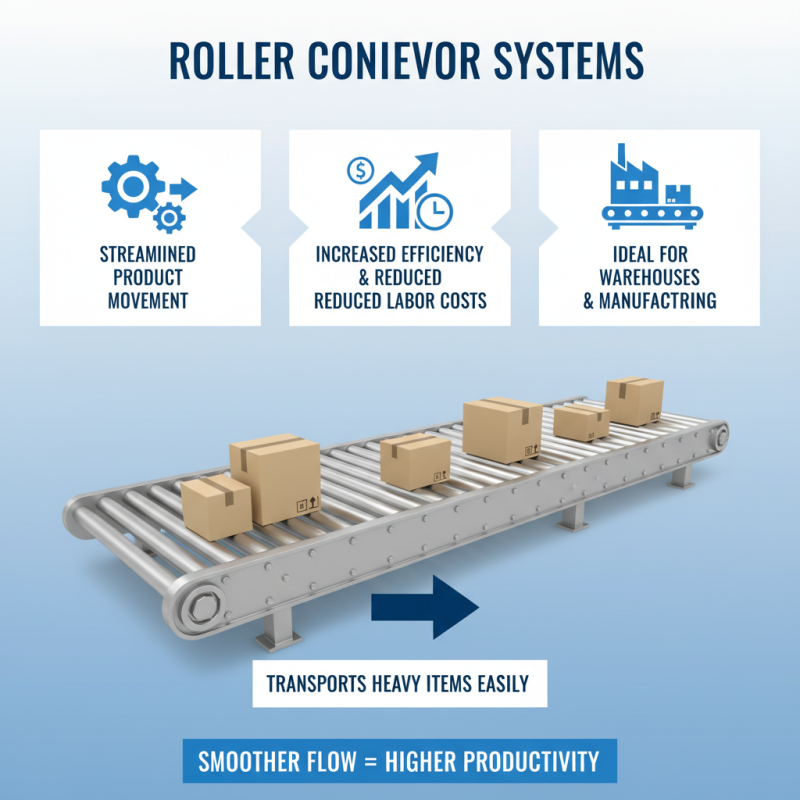

Roller conveyor systems are essential in various industries. They streamline the movement of products. This leads to increased efficiency and reduced labor costs. These systems are particularly useful in warehouses and manufacturing plants. They can transport heavy items easily. When goods flow smoothly, productivity rises.

Using roller conveyors minimizes the risk of damage. For instance, products rarely get dropped. This can save costs on replacements. Additionally, these systems can be customized. Companies can adapt them to specific needs. However, it's important to assess physical space constraints. Poorly planned layouts can hinder efficiency.

**Tips**: Ensure regular maintenance of conveyor systems. This prevents unexpected breakdowns. Also, train staff to use equipment properly. Smooth operation relies on knowledgeable workers. Finally, always measure your workflow. Analyzing performance can reveal areas for improvement. Consider feedback from employees; their insights can be valuable.

Choosing the right roller conveyor system is crucial for efficiency. Several factors play a role in this decision. First, consider the load capacity. Every system has a limit. Understand your product sizes and weights to avoid overloading.

Next, think about the layout of your facility. Is it spacious or compact? Roller conveyors can be customized. They can fit straight paths, curves, or even inclines. Measure the areas where you plan to install the system. Space constraints might limit your options more than you anticipate.

Lastly, don’t overlook maintenance requirements. Some systems need frequent upkeep. Others are more durable. Think about how much downtime you can afford. A roller conveyor might be efficient, but if it breaks down often, it becomes a headache. Reflect on how these factors impact your choice before making a final decision.

| Feature | Description | Considerations |

|---|---|---|

| Load Capacity | The maximum weight the conveyor can safely handle. | Ensure the load capacity exceeds your heaviest items to avoid damage. |

| Roller Diameter | The diameter of the rollers that affect the size and speed of transportation. | Choose a diameter that fits your product dimensions for optimal performance. |

| Conveyor Length | Total length of the conveyor system which affects layout. | Plan your space and ensure the length is sufficient for your workflow. |

| Surface Material | The material used for rollers affects durability and usability. | Select materials that are suitable for the items being transported. |

| Speed Control | Ability to adjust the speed of the roller conveyor. | Consider if variable speed is needed based on your process. |

| Drive Type | Types can include belt-driven, chain-driven, and gravity. | Choose a drive type that fits your operational needs and maintenance levels. |