In the rapidly evolving landscape of manufacturing, optimizing industrial conveyor systems has become pivotal for enhancing operational efficiency. According to a report by the Material Handling Industry of America, effective optimization of conveyor systems can lead to a remarkable 30% increase in productivity while reducing operational costs by as much as 25%. This trend emphasizes the importance of advanced technologies and best practices in the management of conveyor systems, which serve as the backbone of automated material handling processes.

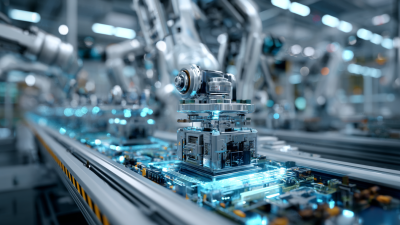

Industry expert, Dr. Sarah Hollis, a recognized authority in logistics and supply chain optimization, asserts, "The future of efficiency in industrial operations hinges on our ability to leverage smart conveyor systems that integrate seamlessly with other automation technologies." This statement underscores the significance of adopting innovative approaches to conveyor system design, including the use of IoT devices, AI-driven analytics, and modular system configurations. As we look towards 2025, the shift toward more intelligent and adaptable industrial conveyor systems will not only enhance production capabilities but also align with sustainability goals that are increasingly vital in today’s market.

In conclusion, understanding and implementing strategies to optimize industrial conveyor systems is crucial for companies aiming to maintain a competitive edge in an era defined by relentless technological advancement and heightened consumer expectations.

Assessing the performance metrics of your current conveyor system is crucial for identifying optimization opportunities. Key metrics such as throughput, downtime, energy consumption, and maintenance frequency provide valuable insights into the operational efficiency of conveyor systems. By establishing a baseline of these metrics, businesses can pinpoint specific areas that require improvement and implement targeted strategies to enhance overall productivity.

**Tips:** First, utilize data analytics tools to monitor and analyze the performance metrics continuously. Identifying patterns in throughput and downtime can help managers devise actionable plans to mitigate inefficiencies. Secondly, engage your workforce in the evaluation process. They often have firsthand knowledge of the system’s pain points and may provide innovative ideas to improve operations.

Additionally, consider benchmarking your conveyor system against industry standards. This comparison can illuminate gaps in performance and reveal cutting-edge technologies or practices that can elevate your system to the next level. By systematically analyzing and refining your metrics, you can create a more efficient, cost-effective conveyor system that supports your broader operational goals.

This chart illustrates the performance metrics of various conveyor systems, providing insights into optimization opportunities based on current efficiency levels.

As industries continue to evolve, the integration of advanced automation technologies into conveyor systems has become paramount for enhancing operational efficiency. According to a report from the International Society of Automation, implementing automated conveyor control systems can increase throughput by up to 30%, significantly reducing the time products spend in transit. With technologies such as AI-driven predictive maintenance, operators can minimize downtime by 20%, ensuring continuous operation and maximizing productivity.

Moreover, the integration of IoT sensors within conveyor systems allows for real-time monitoring and data analysis. This capability leads to optimized performance by identifying bottlenecks and allowing for quicker adjustments to production rates. A study by the Automation Federation indicates that factories utilizing smart conveyor systems experience a 25% reduction in energy costs, a critical improvement in today's energy-conscious environment. By harnessing these advanced technologies, companies not only streamline their processes but also position themselves competitively in an increasingly automated industrial landscape.

To maximize the efficiency of industrial conveyor systems, it is essential to harness the power of data analytics. Recent reports indicate that up to 70% of operational costs in manufacturing are related to material handling, with conveyor systems forming a crucial part of this process. By utilizing advanced data analytics tools, companies can identify bottlenecks within their conveyor systems that lead to delays and inefficiencies. For instance, a study by McKinsey shows that predictive maintenance driven by data insights can reduce downtime by up to 50%, significantly enhancing overall productivity.

Moreover, implementing real-time monitoring and analytics allows for the immediate detection of anomalies in conveyor operations. According to a report from the International Society of Automation, organizations that invest in data-driven optimization strategies can improve their throughput by as much as 30%. By analyzing historical data and establishing key performance indicators (KPIs), businesses can prioritize maintenance schedules and redesign workflows to alleviate identified bottlenecks. This strategic approach not only streamlines operations but also contributes to a more sustainable manufacturing environment, reducing waste and resource consumption.

| Conveyor Type | Length (meters) | Throughput (items/hour) | Current Efficiency (%) | Identified Bottleneck (%) | Proposed Improvement (%) |

|---|---|---|---|---|---|

| Belt Conveyor | 50 | 500 | 85 | 15 | 10 |

| Roller Conveyor | 30 | 600 | 75 | 20 | 15 |

| Chain Conveyor | 40 | 450 | 80 | 10 | 5 |

| Bucket Conveyor | 25 | 300 | 70 | 25 | 20 |

| Magnetic Conveyor | 35 | 350 | 78 | 12 | 8 |

Implementing predictive maintenance strategies is crucial for optimizing industrial conveyor systems and minimizing both downtime and operational costs. By leveraging advanced technologies, such as IoT sensors and machine learning algorithms, businesses can monitor the performance of conveyor systems in real time. This data enables early detection of potential issues before they escalate into costly breakdowns. Additionally, predictive maintenance helps in scheduling maintenance activities when needed, rather than relying solely on fixed schedules, thus reducing unnecessary maintenance costs.

Tips for Effective Predictive Maintenance:

By adopting these strategies, companies can not only enhance the longevity and reliability of their conveyor systems but also improve overall productivity. Implementing a proactive maintenance approach leads to greater resource efficiency and helps maintain smooth operational workflows in industrial settings.

In the pursuit of optimizing industrial conveyor systems, evaluating energy consumption and implementing sustainable practices are paramount. According to a 2022 report by the International Energy Agency (IEA), industrial operations contribute to over 30% of global energy demand. This highlights the critical need for companies to not only enhance efficiency but also minimize their carbon footprints. One effective strategy is the adoption of energy-efficient motors and variable frequency drives (VFDs), which can reduce energy consumption by up to 50% in conveyor systems.

Sustainability practices in conveyor operations also include regular maintenance and monitoring to prevent energy waste. The U.S. Department of Energy suggests that poorly maintained systems can see energy losses of up to 20%. Implementing condition monitoring technologies can further help in detecting inefficiencies early, leading to timely interventions.

Additionally, incorporating smart technology, such as AI-driven analytics, allows for real-time adjustments and optimizations that enhance both performance and sustainability. By focusing on these areas, industries can significantly reduce operational costs while contributing to a greener future.