In today's fast-paced warehousing environment, efficiency and productivity are paramount. The integration of roller conveyors in warehouse operations has become a crucial factor for success, as they significantly streamline the movement of goods and materials. According to the Material Handling Industry of America (MHIA), implementing automated systems, including roller conveyors, can boost operations' efficiency by as much as 50%. This enhancement is essential for businesses aiming to meet increasing consumer demands while managing operational costs effectively.

Expert in material handling systems, Dr. Emily Carter, emphasizes the advantages of roller conveyors, stating, "The adaptability and speed of roller conveyors transform how warehouses operate, allowing for quicker processing and reduced labor costs." In addition to operational efficiency, roller conveyors improve safety measures within warehouses by minimizing manual handling and reducing the risk of workplace injuries. As businesses continue to invest in automation and modern technologies, the roller conveyor system stands out as a vital component in optimizing warehouse productivity.

Roller conveyors have become an essential component in modern warehouse operations, providing significant enhancements in efficiency and productivity. These systems allow goods to move smoothly and quickly across facility floors, minimizing manual labor and reducing the time spent on moving products from one point to another. According to a report by the Material Handling Industry of America, the use of automated conveyor systems can increase productivity by up to 50%, significantly impacting overall operational efficiency.

In addition to productivity gains, roller conveyors help improve safety in the workplace. With the ability to transport heavy items without requiring manual handling, the risk of workplace injuries decreases considerably. The Bureau of Labor Statistics reports that workplaces utilizing automated material handling systems can see a reduction in workplace injury rates by as much as 40%. Furthermore, roller conveyors can be customized to fit specific warehouse layouts, making them adaptable to a variety of environments, which maximizes space utilization and streamlines operations. As logistics demands continue to grow, implementing roller conveyor systems can provide a strategic advantage by enhancing overall effectiveness in warehouse management.

| Benefit | Description | Impact |

|---|---|---|

| Increased Efficiency | Roller conveyors help to speed up the movement of goods in the warehouse. | Boosts productivity by reducing handling time. |

| Space Optimization | Roller conveyors take up less space than traditional handling methods. | Maximizes the use of available warehouse space. |

| Reduced Labor Costs | Automation of material handling with roller conveyors minimizes manual labor. | Cuts down on workforce expenses. |

| Improved Safety | Less direct handling of heavy items reduces the risk of injury. | Enhances workplace safety and reduces liability. |

| Versatility | Roller conveyors can handle a variety of products and package types. | Supports diverse warehouse operations. |

| Quick Installation | Easy to install and integrate into existing systems. | Minimizes downtime during setup. |

| Reduced Wear on Products | Gentler handling of goods compared to manual systems. | Minimizes damage to products, preserving quality. |

| Streamlined Operations | Facilitates smoother flow of inventory through the warehouse. | Enhances overall operational efficiency. |

| Cost-Effectiveness | Long-term savings through improved efficiency and reduced labor costs. | Yields a higher return on investment. |

| Enhanced Inventory Management | Improves tracking and management of stock levels. | Enables better decision-making regarding inventory. |

Automated material handling is revolutionizing warehouse operations, and roller conveyors play a pivotal role in this transformation. By incorporating roller conveyors into a warehouse system, companies can significantly enhance efficiency in the movement and management of goods. These conveyors facilitate the smooth transportation of items from one location to another, reducing the time spent on manual handling. With their ability to seamlessly integrate with automated systems, roller conveyors ensure that products are consistently and quickly delivered to their destinations, minimizing delays and optimizing workflow.

Moreover, roller conveyors contribute to improved safety in warehouse settings. By automating the movement of materials, the risk associated with human interventions is considerably lowered. Workers can focus on more complex tasks that require critical thinking, while the conveyors handle repetitive and physically demanding duties. This shift not only boosts productivity but also fosters a safer and more ergonomic work environment. As a result, businesses can maintain a steady operational pace, ultimately driving higher throughput and customer satisfaction.

This bar chart showcases the top 10 benefits of using roller conveyors in warehouse operations, illustrating the significance of each benefit in enhancing efficiency through automated material handling.

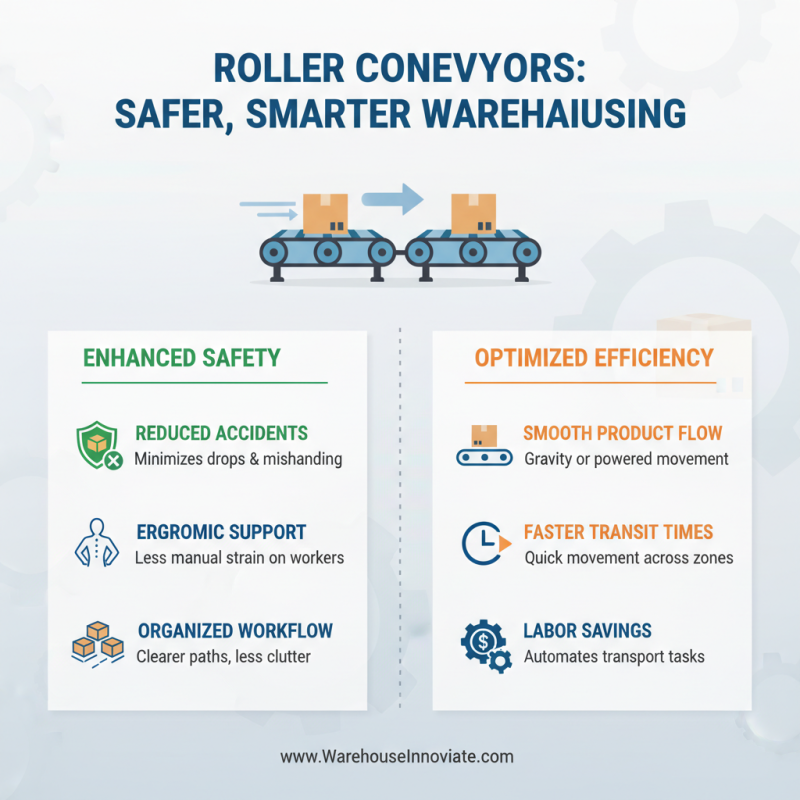

Roller conveyors play a pivotal role in enhancing safety and minimizing labor strain in warehouse operations. By utilizing gravity or powered roller systems, these conveyors facilitate the smooth movement of goods across various warehouse areas. This reduces the risk of accidental drops or mishandling, which are common when products are manually transported. The design of roller conveyors promotes a more organized and streamlined workflow, allowing employees to navigate the warehouse with ease and reducing clutter that can lead to accidents.

Additionally, the ergonomic benefits of roller conveyors significantly alleviate labor strain on workers. When heavy items need to be moved, relying on manual lifting can lead to fatigue and potential injuries over time. Roller conveyors minimize physical exertion by enabling employees to push or guide items instead of lifting them. This not only enhances worker safety but also increases productivity, as employees can focus on other essential tasks rather than overexerting themselves. By integrating roller conveyors into warehouse operations, companies can create a safer, more efficient working environment that ultimately leads to enhanced employee satisfaction and performance.

Roller conveyors are an essential component of warehouse operations, particularly when it comes to achieving long-term cost savings. One of the primary advantages is their ability to enhance workflow efficiency. By facilitating smooth and rapid movement of goods, roller conveyors minimize the time taken to transport products within the warehouse. This increased efficiency lowers labor costs significantly, as fewer workers are needed to handle manual transport tasks.

Over time, the reduction in labor requirements translates into substantial financial savings for facilities relying on these systems.

Moreover, roller conveyors are known for their durability and low maintenance needs, which further contribute to cost reductions. Most roller systems are designed to withstand heavy loads and ongoing use without degrading in performance. This durability means fewer interruptions due to breakdowns and repairs, allowing for continuous operation and increased productivity. As warehouses invest in roller conveyor systems, the initial setup costs are quickly offset by the savings gained from decreased maintenance expenses and increased reliability, solidifying the long-term financial benefits of implementing such systems in warehouse operations.

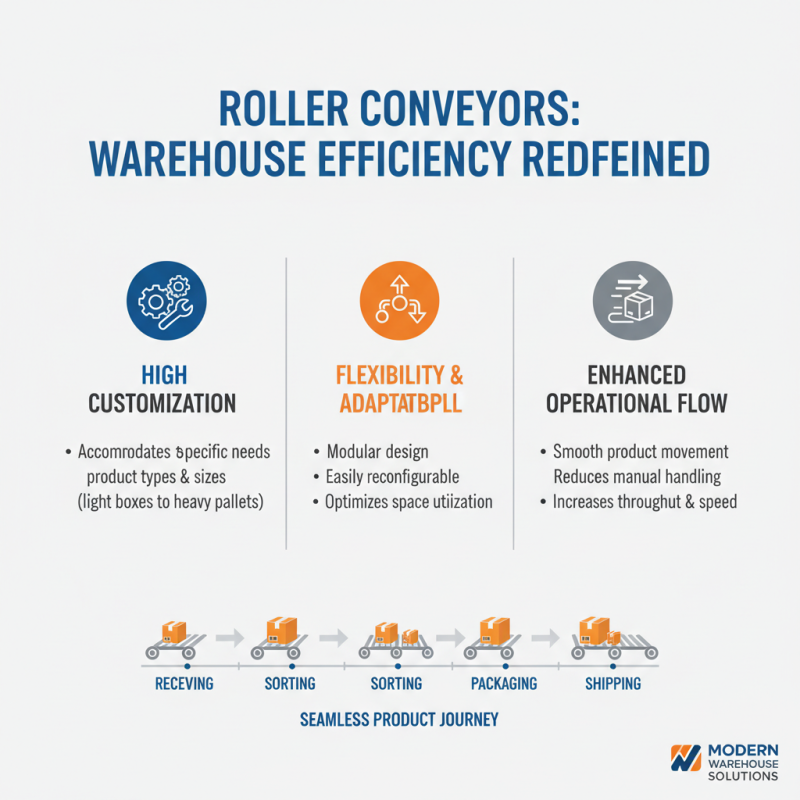

Roller conveyors have become an essential element in modern warehouse operations, primarily due to their high degree of customization and flexibility. Unlike fixed systems, roller conveyors can be designed to meet the specific needs of various industries. They can accommodate a wide range of products, from lightweight boxes to heavy pallets, allowing businesses to tailor their systems according to the types and sizes of goods handled. This adaptability helps optimize space and enhances efficiency by ensuring that products can be moved smoothly through different station points within the warehouse.

Moreover, the modular design of roller conveyors allows for easy reconfiguration as warehouse needs evolve. Companies can expand or modify their systems without significant downtime or cost, making roller conveyors particularly beneficial for businesses anticipating growth or changes in product lines. This flexibility not only maximizes operational efficiency but also enables better project management, as companies can quickly pivot their logistics strategies to meet market demands or seasonal shifts. Overall, the customizable nature of roller conveyors plays a crucial role in streamlining warehouse operations and promoting a more agile supply chain.