In the ever-evolving landscape of modern industries, efficiency and productivity are paramount. One of the pivotal innovations making waves in material handling solutions is the roller conveyor belt. These systems are increasingly being adopted across various manufacturing and logistics sectors due to their ability to streamline operations and enhance workflow. The roller conveyor belt serves not only as a mechanism for transporting goods but also plays a crucial role in reducing manual labor, thereby minimizing the risk of workplace injuries and improving overall operational reliability.

The advantages of implementing roller conveyor belts are numerous. They provide a reliable means of moving products or materials across different points in a facility, significantly saving time and labor costs. Furthermore, roller conveyor belts can be customized to accommodate a wide variety of loads and sizes, making them adaptable to different industrial needs. By employing this advanced handling system, industries can achieve greater productivity levels and maintain competitive edges in today’s market. As we explore the top ten advantages of using roller conveyor belts, it becomes clear how these systems have revolutionized operational efficiency in modern industrial environments.

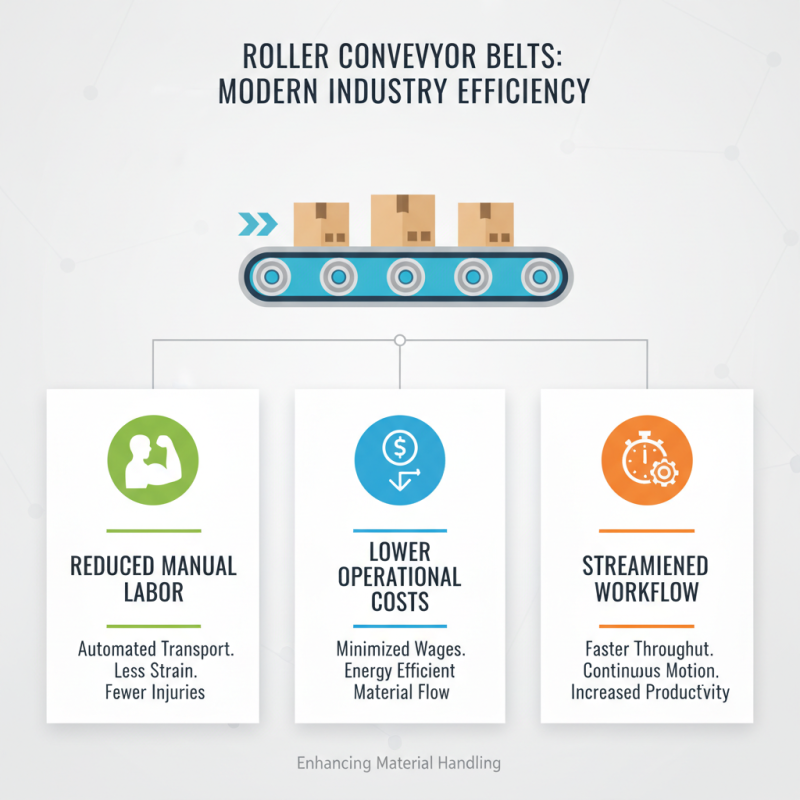

Roller conveyor belts play a pivotal role in modern industries by significantly enhancing material handling efficiency. One of their primary advantages is the reduction of manual labor required in the transportation of goods. With a roller conveyor system, products can be smoothly moved from one point to another with minimal human intervention, resulting in decreased operational costs and reduced risk of injury for workers. This automated movement also allows for a more streamlined workflow, as materials can be transported quickly and efficiently throughout the facility.

Moreover, roller conveyor belts offer versatility in handling a wide range of products, from lightweight items to heavier loads. This adaptability ensures that different types of materials can be managed without the need for multiple handling systems, simplifying the logistics process. The ability to customize roller conveyor layouts to fit specific operational needs further enhances efficiency, allowing companies to optimize their space and improve productivity. By integrating roller conveyor belts into their material handling processes, industries can achieve significant improvements in speed, safety, and overall operational efficiency.

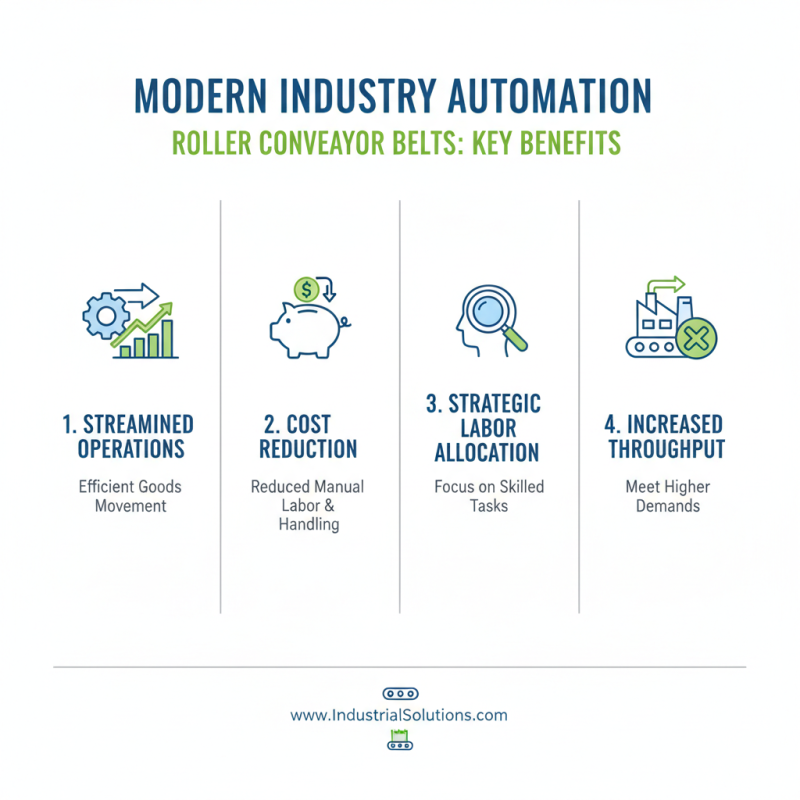

In modern industries, roller conveyor belts have emerged as a pivotal element in streamlining operations and cutting costs. By facilitating the efficient movement of goods, these conveyor systems significantly reduce manual handling and labor costs. This automation allows companies to allocate their human resources more strategically, focusing on skilled tasks rather than routine material transport. The potential for increased throughput means that businesses can meet higher demands without proportionately increasing operational expenses.

Moreover, roller conveyor belts contribute to minimized equipment wear and tear. With their ability to distribute loads evenly, these systems lower the likelihood of damage to products and the infrastructure itself. This reduction in maintenance and repair costs can result in substantial savings over time. Additionally, the energy efficiency of roller systems, compared to other forms of conveying methods, leads to lower utility bills, further enhancing the profitability of industrial operations. Overall, the integration of roller conveyor belts offers a comprehensive approach to not only improve efficiency but also to drastically cut operational costs, making them an indispensable asset in contemporary industrial settings.

Roller conveyor belts have emerged as a vital component in modern industries, primarily due to their significant impact on production speed and throughput. Designed to efficiently transport materials across various manufacturing and logistics processes, these systems ensure that items are moved quickly from one stage to another, reducing idle time and enhancing overall productivity. The smooth operation of roller conveyor belts minimizes the risk of jams and delays, allowing for uninterrupted workflows that are essential in high-demand environments.

In addition to accelerating movement, roller conveyor belts contribute to optimizing production lines by enabling better organization and handling of goods. With the ability to support various load types and sizes, these conveyors facilitate seamless transfers between different processing areas, thereby maximizing throughputs. The integration of roller conveyors not only fosters a more synchronized operational flow but also enhances the ability to meet stringent deadlines and increasing order fulfillment rates. As industries continue to evolve, leveraging the advantages of roller conveyor belts becomes crucial for staying competitive in fast-paced markets.

| Advantage | Description | Impact on Production |

|---|---|---|

| Increased Speed | Roller conveyor belts allow faster transportation of materials across the production line. | Boosts overall efficiency and reduces cycle time. |

| Versatility | Can handle a variety of product sizes and shapes. | Enables adaptation to different production needs. |

| Reduced Labor Costs | Minimizes the need for manual handling of materials. | Allows workforce to focus on higher-value tasks. |

| Space Efficiency | Compact design can save floor space in warehouses and factories. | Optimizes layout for better workflow. |

| Durability | Made from strong materials that withstand heavy loads. | Decreases downtime due to repairs. |

| Low Maintenance | Requires less frequent maintenance compared to other conveyor systems. | Lowers operational costs. |

| Safety Features | Equipped with safety guards and emergency stops. | Reduces risk of accidents in the workplace. |

| Energy Efficiency | Designed to consume less power during operation. | Decreases energy costs over time. |

| Improved Workflow | Facilitates seamless transport of items along production lines. | Enhances productivity and efficiency. |

Roller conveyor belts are integral to modern industries, particularly due to their substantial safety benefits in workplace environments. According to a report by the Conveyor Equipment Manufacturers Association (CEMA), conveyor systems can reduce workplace accidents by up to 40% when properly utilized. These systems streamline the movement of materials, minimizing manual handling, which is a primary cause of musculoskeletal injuries among workers. The automated nature of roller conveyor belts not only enhances efficiency but also decreases the likelihood of slips and falls associated with material transport.

In addition to reducing physical strain, roller conveyor belts are designed with safety features such as emergency stop buttons and conveyor guards, ensuring a safer working environment. The Occupational Safety and Health Administration (OSHA) reports that properly maintained conveyor systems can significantly lower the risk of accidents related to machinery, which accounted for nearly 18% of all workplace injuries in the manufacturing sector in 2022. Implementing roller conveyor systems not only aligns with safety regulations but also fosters a culture of safety, leading to higher employee morale and lower turnover rates. These advantages make roller conveyor belts an essential component in promoting workplace safety and operational efficiency.

The following bar chart illustrates the key safety benefits offered by roller conveyor belts in workplace environments. Each benefit is quantified based on its importance and effectiveness in enhancing safety measures within industrial operations.

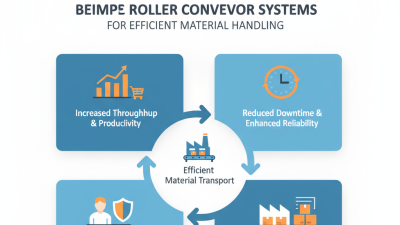

Roller conveyor belts are increasingly becoming an essential component in modern industries, particularly due to their effectiveness in minimizing downtime and maintenance needs. These systems boast higher reliability compared to traditional conveyor systems, significantly reducing the frequency of breakdowns. With their robust design, roller conveyor belts can handle heavy loads with ease and require less frequent repair or replacement, making them a cost-effective solution over time.

Another critical advantage of roller conveyor belts is their ability to streamline operations, enabling faster material movement. This increase in efficiency translates into reduced operational delays, which is crucial for industries where time is money. Moreover, the maintenance of roller conveyor systems is often simplified due to their modular design; components can be easily accessed and replaced, further reducing downtime. This ease of maintenance allows companies to allocate resources more effectively, ensuring that production processes are uninterrupted and continue to meet demand without excessive delays.